Projects carried out by Prathit Automation

Through our Services, we are committed to our client’s business needs, for improved plant performance. We provide cost-effective alternatives for complex requirements, by building customer-specific solutions on simple and reliable technology.

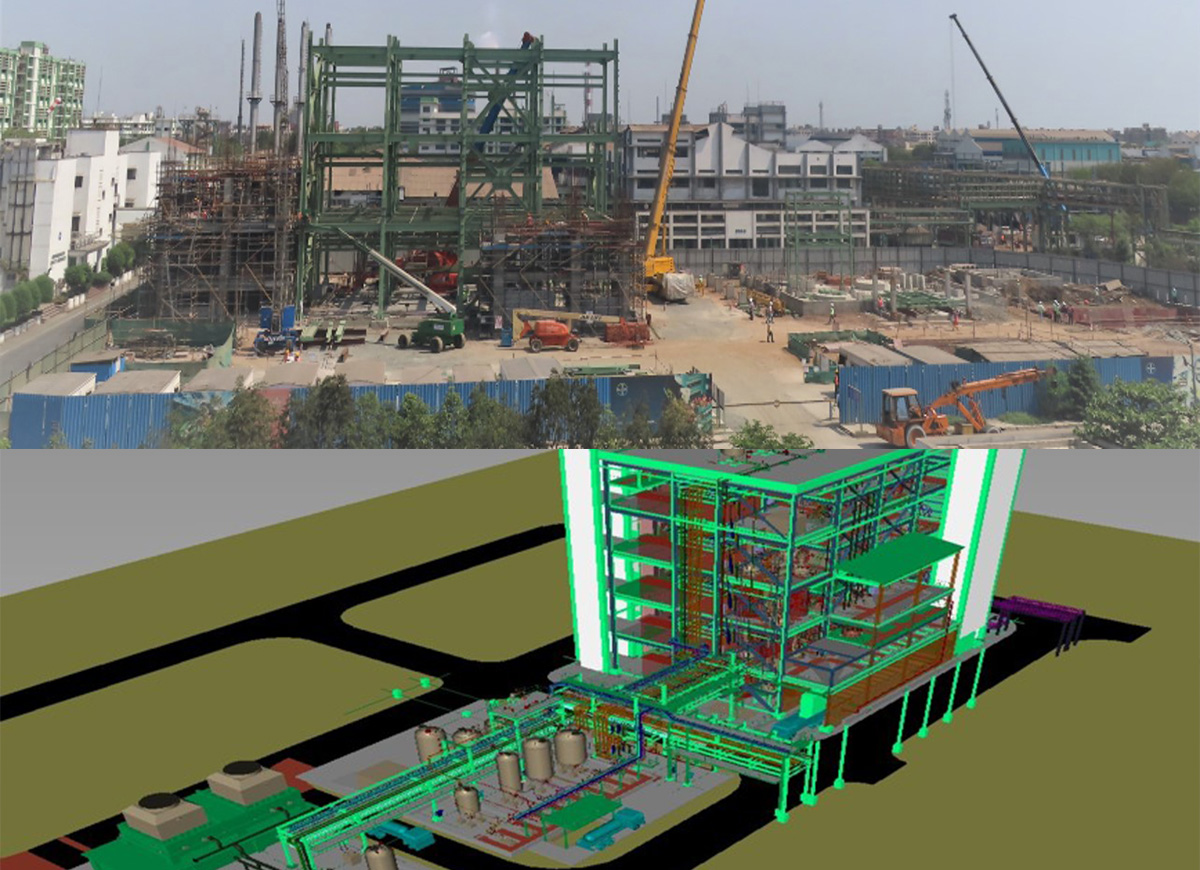

Bayer Project References

New DICO

Owners engineering support (PMC) for a Greenfield project from concept to commissioning. To erect a modern, safe & automatic plant for the production of AI intermediate (Project Investment: €42m)

Key statistics

- Equipment – 700 nos.

- I/O counts – 7000

- Mechanical Completion: 08/2018

Delta V DCS system with conventional 7000 I/O HART signals. Safety instrumented system Delta-V for 400 I/O. Stare of art field instrumentation for critical parameter control like pH, Conductivity, Level measurement.

Ferring Pharma Project

Ambernath

Owners engineering support (PMC) for a Greenfield API project. Validation document development as per FDA requirement. To build a state of the art facility for mfg. of 300 T/A API (Project Investment: €25m).

Key statistics:

- DCS biased Automatic Operations

- I/O counts – 2500

DCS biased plant with state of art field instruments with FF protocol. iMCC with Profibus protocol, Remote Digital I/O with Profibus protocol.

- pH system with Auto retracement and Auto-cleaning.

- Hardware safety system panel.

- Smart Plant Instrumentation (INTools) for Instrumentation design, database development, and documentation

Catasynth (Anthea Group) Project

Mangalore

- Fine Chemical plant project

- Investment ~ 2500 mio INR

- Greenfield Project

Detail Engineering and installation commissioning of the Plant Automation System.

- DCS system from Yokogawa – 4500 I/O

- iMCC from Siemens on Profibus

- Remote I/O on Profibus

- AI/AO conventional HART instruments

Installation and commissioning of 3000 instruments, cable tray, cable laying, pneumatic tubing and hardware fabrication and installation in six plants, complete Fiber network for plant-wide instrumentation and control systems.

Bayer Project

EPRO

Owners engineering support (PMC) for a Greenfield project from concept to commissioning. To erect a modern, safe & automatic plant for production of AI molecule (Project Investment: €25m)

Key statistics:

- Equipment – 240 nos.

- I/O counts – 3000

Project construction management team engineers and safety officers to oversee complete construction activity. Safe execution of project equipment installation with all safety precautions.

NALCO Project

Angul

Engineering & PMC support for various projects

- Engineering for HFO system (Unloading, storage & transfer system from Railway Wagons).

- Activities involved.

- Design, Development of P&Id, and Engineering of a complete system.

- Design, Supply, Installation, and commissioning of Automation and Electrical system.

- Design, Supply, and installation of field instrumentation with flow metering and distribution with mass flowmeters.

- Design of Heat tracing system for Storage Tank and Transfer lines.

- Plant as-built documentation.

- Project commissioning support.

BASF Project

Dahej

Automation & PMC support for Execution of Chemical plant (Cellasto project)

- Turnkey Design, Supply, Installation and commissioning of Heating system

- Tank farm Automation with Remote I/O system

- PMC for Cellasto project

BASF Project

Ankleshwar

Engineering & PMC support

- Design of DCS & ESD system along with field devices

- Design and Detail Engineering services for Unit II

Turnkey Design, Supply, Installation and commissioning of Project work

- Project Management support

- Field Instrumentation Audit and documentation for plant II

NOCIL Project

Detail Engineering- Design and development of P&Id, control philosophy, detail engineering documentation, and Supply, Installation & commissioning of Automation Systems for various Chemical plant.

- Basic engineering for conversion of the Batch process to a continuous process for Rubber chemical plants

- Design and Detail engineering for Pastillator unit controls with indigenous instruments.

- Design and Detail engineering for Anti-oxidant, Accelerator unit

- Supply, Installation, and commissioning of the Automation system for various plants. Includes Cable tray, Cable, hardware, and SS tubing for various instruments. Installation of DCS system panels, termination, loop checking, and commissioning of plant systems.

Owens Corning Project

Taloja

Instrumentation Supply, Installation, and commissioning project work. Machine modification with safety feature up-gradation, PLC system replacement

- Supply and installation of control panels for the roving system with safety features up-gradation

- Cable Trays -6500 m, Cable Glands, Junction Boxes

- Inst. Tubing SS-5000 mtr, PU tubing -4500 mtr, Fittings and valves

- Air Header- 20 nos, Condensation Pots

- Field Instruments 603,

- PLC Panels- 80

Cable- 99000m, cable trays-6500m, Junction Boxes, Inst. Tubing ss- 5000m, PU- 4500m

Jubilant Project

Mysore

Plant Validation document development, and Instrumentation installation and commissioning supervision work carried out for Emerson. Turnkey supplier to Jubilant manufacturing plant) Main activity in various projects includes,

- Design Verification, Installation Qualification, PQ/ OQ support and commissioning services for the project

- DCS system Validation documentation as per 21 CFR requirements.

- Detail Engineering documentation for Plant Instrumentation – datasheets, JB/ Cable schedule, Loop drawings, Hook up drawings,

- Project commissioning support